Industrial Panel PC in the Automation control system, that is divided into capacitive touch and resisitive touch according to touch type.

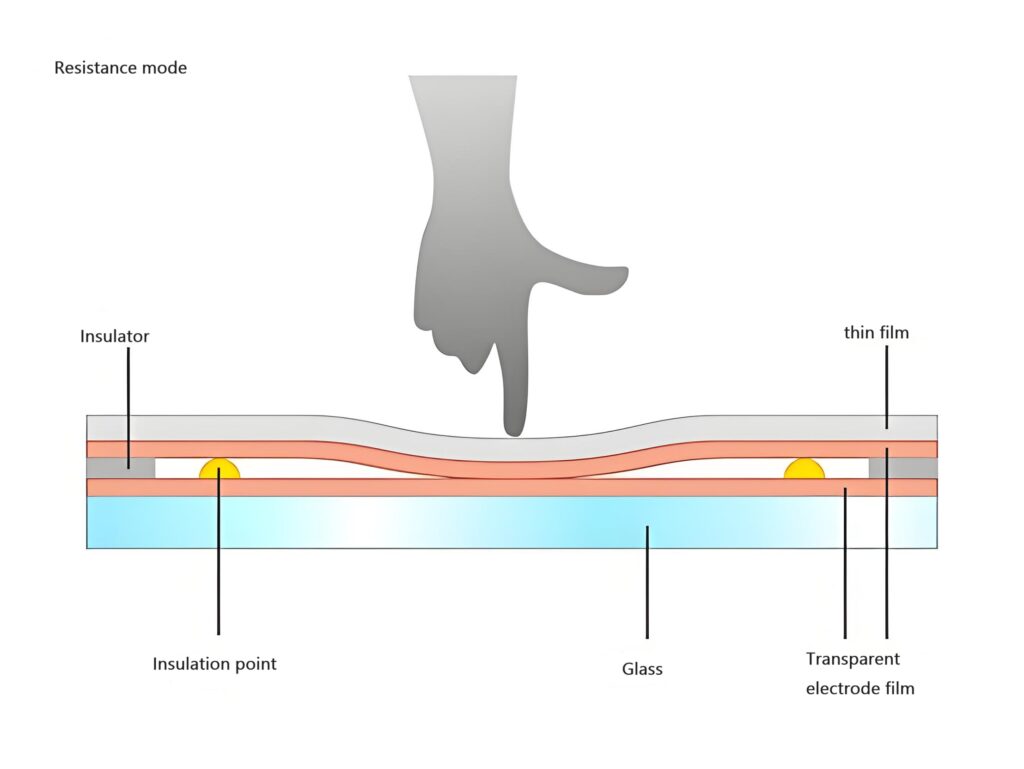

About of resistive screen

Resistive touch screen is a sensor that converts the physical position of the touch point (X, Y) in a rectangular area into voltage representing the X coordinate and Y coordinate. Many LCD modules use resistive touch screens. This screen can use four, no, seven or eight lines to generate screen bias voltage and read back the voltage of the touch point.

Advantages of resistive touch screen

1. The precision of resistive touch screen is high, which can reach the level of pixel points, and the maximum resolution can reach 4096*4096.

2. The screen is not affected by dust, water vapor and oil, and can be tested in low or high temperature environments.

3. Resistive touch screen uses pressure sensing, which can be touched with any object, even with gloves, and can be used for handwriting recognition.

4. Resistive touch screen is relatively cheap due to mature technology and low threshold.

Disadvantages of resistive touch screens

1. Resistive touch screens can be designed for multi-touch, but when two points are pressed at the same time, the pressure on the screen becomes unbalanced, resulting in touch errors, so multi-touch is difficult to achieve.

2. Resistive touch screens are more likely to be damaged by scratches, etc.

About capacitive touch screen

Capacitive touch screen technology uses the current induction of the human body to work. When a finger touches the metal layer, the human body electric field forms a coupling capacitor between the user and the touch screen surface.

For high-frequency current, the capacitive type directly blocks the problem, so the finger absorbs a very small current from the touch. This current flows out from the electrodes on the dead corners of the touch screen, and the current flowing through these four electrodes is proportional to the distance from the finger to the four corners. The controller obtains the position of the touch point by accurately calculating the ratio of these four currents.

Advantages of capacitive touch screen

1. Capacitive screens only require touch, not pressure to generate signals.

2. Capacitive touch screens only require one or no calibration after production, while resistive technology requires regular calibration.

3. The life of the capacitive solution will be longer because the components in the capacitive touch screen do not need to move at all. In the resistive touch screen, the upper ITO film needs to be thin enough to be flexible so that it can bend downward to contact the lower ITO film.

4. Capacitive technology is superior to resistive technology in terms of light loss and system work number.

5. The choice of capacitive technology or resistive technology mainly depends on the object touching the screen. If it is a finger touch, capacitive touch screen is a better choice. If a stylus is needed, whether it is plastic or metal, resistive touch screen can do the job. Capacitive touch screens can also use a stylus, but a special stylus is required to cooperate.

6. Cousin capacitive type can be used for large-sized touch screens, and the relative cost is also low, but it cannot support gesture recognition at present: inductive capacitive type is mainly used for small and medium-sized touch screens, and can support gesture recognition.

7. Flashlight technology is wear-resistant and has a long life. The maintenance cost is low when the user uses it, and the overall operating cost of the film manufacturer can be further reduced.

8. The transmittance and clarity of the capacitive touch screen are better than the four-wire resistive screen, and it cannot be compared with the surface acoustic wave screen and wireless resistive screen at that time. The capacitive screen has serious reflection, and the four-layer load touch screen of the capacitive technology has uneven transmittance of each wavelength of light, and there is a problem of color distortion, which is better than the reflection of light between the layers, and also causes the image characters to be blurred.

Whats is the difference between resistive screen and capacitive screen ?

1. The capacitive screen works by using the current induction of the human body, so any non-conductive objects such as nails, gloves, etc. cannot be recognized by the capacitive sensing system under the screen. The resistive screen works by pressure sensing, and can be touched with any object, and supports stylus.

2. Multi-touch of the capacitive screen is achievable, depending on the implementation method and the software used. Multi-touch of the resistive screen is not achievable unless the resistive screen is reorganized and connected to the circuit of the machine.

3. The outermost layer of the capacitive screen is a silica glass protective layer, which may break under severe impact, while the outermost layer of the resistive screen is a thin film, which needs to be pressed down to achieve pressure sensing.

How to choose a resistive screen or a capacitive screen for an industrial Panel PC ?

Resistive screens are suitable for industrial sites with oil stains, dust, glove operation, large electromagnetic interference, and waterproof treatment. These are the most suitable application scenarios for resistive screens. The working principle of a resistive screen is single point touch, which requires a certain amount of force to take effect when clicked. It is more suitable for devices with lower HMI operation frequency. Resistive screens can only be clicked with fingers or specialized touch screens. Remember not to use metal tools to click, otherwise it can easily cause damage. So what aspects should we pay attention to when using capacitive screens in industrial computers? Firstly, capacitive screens are multi touch devices, especially suitable for devices with frequent HMI human-machine interface operations and multiple functional operations. Capacitive screens are suitable for devices with minimal interference, no need to wear professional gloves, and no obvious water droplet condensation. Grounding of capacitive screens and their devices is necessary to eliminate electromagnetic interference and the impact of human static electricity on touch..

Now you know whether the resistive screen or the capacitive screen is more suitable for your needs when purchasing our industrial pc products? Welcome to contact us for consultation www.touchpctek.com